Homegrown robots are marching into Chinese factories

China is the world's largest industrial robot market, accounting for 51.9% of the global industry with 268,200 robots newly installed in 2021. The greatest use of industrial robots is in the electronics and electrical industry, with demand growing since the pandemic. International manufacturers have long dominated the sector, but Chinese manufacturers of industrial robots are catching up. What obstacles would they need to tackle?

(By Caixin journalists Zhai Shaohui, Qin Min, Qi Zhanning and Hao Shuai)

Chinese industrial robot manufacturers are gearing up to challenge the long-established dominance of global giants by taking advantage of the expanding demand from China's booming domestic electronics industry and the need to upgrade manufacturing.

The domestic share of industrial robots in China doubled from 17.5% in 2015 to 35.5% in 2022, according to MIR Databank. The growth of Chinese robot companies accelerated significantly over the past few years partly due to supply chain disruptions that made it harder to access foreign products and partly because of a growing need for automation in small and midsize manufacturing companies amid pandemic-era labour shortages.

Room for growth

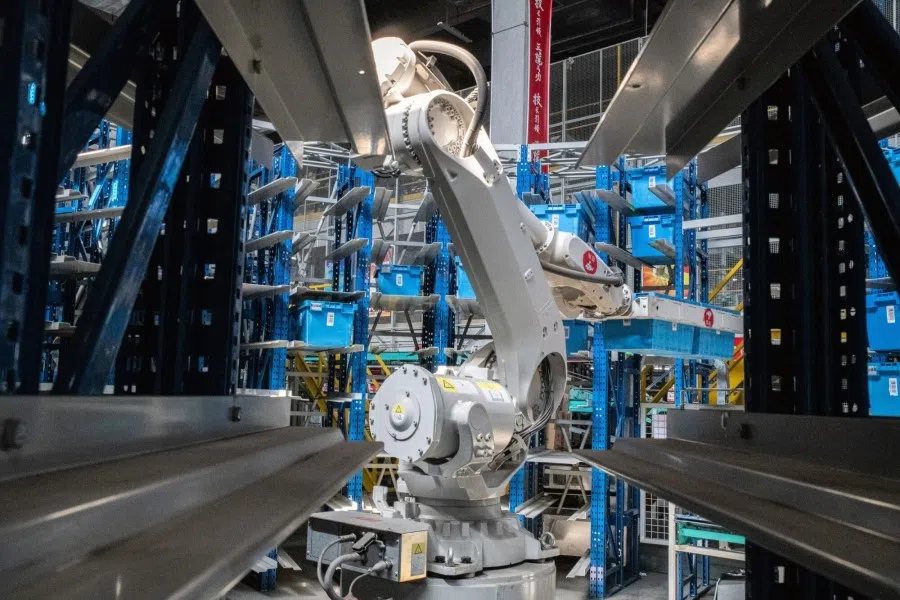

Industrial robots, with robotic arms being the main component, play a crucial role in factory automation. Originating in the late 1950s, industrial robots grew alongside the development of manufacturing in Western countries. China began exploring industrial robots in the 1980s and started commercialising them on a large scale in the 2000s.

In 2022, the global industrial robot market grew to be worth US$18.2 billion. Its size is expected to expand almost eightfold by 2031 to US$151.4 billion, according to market research firm Astute Analytica.

International manufacturers represented by Kuka AG, ABB Ltd., Fanuc Corp. and Yaskawa Electric Corp. have long dominated the sector. In China, foreign companies have long maintained a market share of more than 60%. In the first half of 2022, 12 of the top 20 industrial robot suppliers in China were foreign companies, according to data from MIR Databank. Fanuc held a leading position, and the only two Chinese manufacturers in the top ten were Estun Robotics and Inovance Tech, ranking fifth and seventh.

For Chinese robotic companies to expand their footprint in the market, they need to seek breakthroughs in the fields of core parts, operating systems and algorithms...

Chinese manufacturers are still unable to shake the dominance of foreign competitors in the large industrial robot sector, where higher technology and quality are required, analysts said. But the market has been expanding rapidly, offering domestic players greater room for growth.

According to International Federation of Robotics (IFR), China is the world's largest industrial robot market, accounting for 51.9% of the global industry with 268,200 robots newly installed in 2021. The Chinese Institute of Electronics predicts that the size of the Chinese industrial robot market will reach US$11.5 billion by 2024.

"In the past, domestic industrial robots were mainly used for tasks such as handling, palletising, loading and unloading, and low-end welding," said Wang Jiegao, the former general manager of Estun Automation Co. Ltd. and a former member of the IFR executive board. "Now, they are gradually expanding into high-end tasks such as assembly, polishing, gluing, and spraying, and are entering industries previously monopolised by foreign robot manufacturers."

For Chinese robotic companies to expand their footprint in the market, they need to seek breakthroughs in the fields of core parts, operating systems and algorithms, analysts said.

... the pandemic sped up the popularisation of robots. The disruptions and economic pressure made companies realise that excessive reliance on manual labour brings uncertainty. - Wang Feili, a China machinery industry analyst at UBS Securities

Seizing opportunities

The largest user of industrial robots is the electronics and electrical industry, accounting for 26.5% of global new robot installations in 2021, according to the IFR. In China, the proportion was even higher at 32.8%. China is a major producer of electronic and electrical equipment, especially the "3C products" - computers, communications and consumer electronics. China is also a hub for intelligent manufacturing.

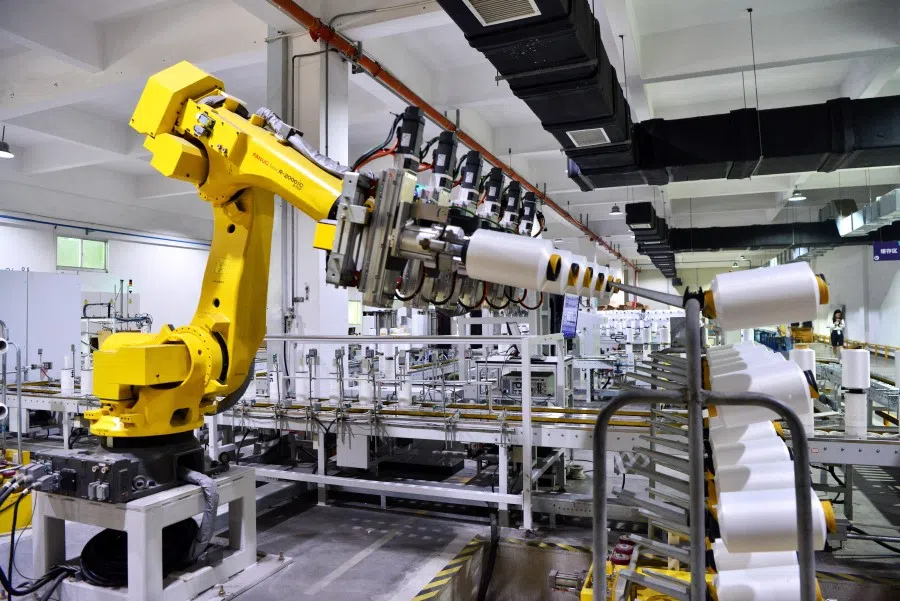

Gu Xiaochun, an expert in intelligent manufacturing at Midea Group Co. Ltd., said the traditionally labour-intensive home appliance industry embraced automation in response to rising labour costs and labour shortages. Intelligent manufacturing also helped the cost-sensitive home appliance industry improve efficiency.

According to Gu, Midea has achieved a high automation rate in core parts such as magnetrons, compressors and motors. Midea also installs robots for general processes such as screwing, handling, palletising, labelling, packaging and inspection. He said the number of robots per 10,000 employees in Midea increased from fewer than 200 in 2020 to 550 within three years.

Chen Guishun, director of the Robot Product Department at Inovance Tech, said the Chinese electronics industrial chain developed rapidly in the past few years thanks to the growth of Apple Inc. and Huawei Technologies Co. Ltd., creating high demand for automation. Chen said large enterprises already enabled a high level of automation, and the orders came from small and midsize companies facing labour shortages.

Compared with automotive industry where advanced industrial robots are widely used, the electronics industry has lower technology requirements on robots, said Wang Feili, a China machinery industry analyst at UBS Securities. The increasing use of small industrial robots by electronics manufacturers provided more business opportunities for domestic robot-makers, Wang said.

Wang said the pandemic sped up the popularisation of robots. The disruptions and economic pressure made companies realise that excessive reliance on manual labour brings uncertainty. As China's economy recovers in 2023, companies are more willing to invest in automated production lines, she said.

Driving up demand

Automaking is another key market for industrial robots. Electric car startup XPeng Inc.'s factory in Zhaoqing, South China's Guangdong province, underwent two upgrades during the Lunar New Year holidays in 2021 and 2022, adding around 130 industrial robots for outer panel welding.

... many automakers still have concerns over the accuracy and repeatability of Chinese industrial robots.

GAC Aion New Energy Automobile Co. Ltd. has two factories in Guangzhou, deploying nearly 1,000 industrial robots. Wang Zhenyu, deputy director of the process department at the Aion Vehicle Technology Center, told Caixin that the auto industry's demand for industrial robots was high around 2012 because of the global economic slowdown, rising labour costs and low industrial robot prices.

Imported robots still dominate Chinese auto production lines. Xpeng's Zhaoqing factory uses robots from international giants such as Fanuc, Kuka and ABB. The robots at Aion's factories also mainly come from the same manufacturers. An automotive industry insider said that many automakers still have concerns over the accuracy and repeatability of Chinese industrial robots.

The rise of China's new-energy vehicles provides opportunities for Chinese industrial robots. Factories making traditional fuel-powered vehicles are dominated by robots from international enterprises, making it difficult for Chinese robots to break in, UBS's Wang Feili said.

"However, many new-energy vehicle brands are from China, and they are more open to domestic supply chains," Wang said. Some automakers are trying to use Chinese industrial robots, although the usage is still limited, she said.

China-made collaborative robots, or "cobots", are becoming the rising stars of the auto industry. Cobots can work collaboratively with workers in the same space.

Chinese industrial robots have entered the auto parts market. Qin Xin, deputy general manager of the XPeng Zhaoqing factory, said many of Xpeng's parts suppliers have deployed robots from Chinese brands Siasun Robot & Automation Co. Ltd., Efort Intelligent Equipment Co. Ltd. and Estun in tasks including welding, handling and palletising. However, the overall share of Chinese robots is still less than 10%. Many upstream parts manufacturers have embraced automation due to rising labour costs, standardisation and quality control, Qin said. They tend to choose cost-effective Chinese robots.

China-made collaborative robots, or "cobots", are becoming the rising stars of the auto industry. Cobots can work collaboratively with workers in the same space. Compared with traditional industrial robots, collaborative robots are safer, more flexible and easier to use.

For example, robot-maker Aubo's cobots have entered multiple automotive production lines, and their shipments in the auto industry accounted for more than 20% of total volume in 2022.

Multiple industry insiders told Caixin that BYD Co. Ltd. purchased around 20,000 industrial robots in 2022, of which 1,000 were Aubo cobots used in tasks for handling, screwing and glueing.

An ABB China representative told Caixin that comparing traditional industrial robots with cobots driven by artificial intelligence technology is like comparing fuel-powered vehicles with EVs.

Industry insiders say that if a virtuous cycle can be created, the Chinese robot industry will undoubtedly expand in the next five to ten years.

Maturing supply chain

In recent years, many foreign industrial robot companies entered China to build factories, driving localisation of the supply chain. Inovance Tech's Chen told Caixin that the localisation of the industrial robot supply chain is accelerating. For example, basic parts such as castings are mainly produced in China.

Wei Hongxing, chair of Aubo, estimated that the current localisation rate of the industrial robot supply chain is about 30%. In comparison, cobots have lower technology requirements for speed and accuracy, making it easier for Chinese suppliers to enter the market. Currently, almost all core parts of Chinese cobots are produced domestically except the operating system and specialised chips.

The development of the local supply chain makes Chinese industrial robots more competitive. Industry insiders say that if a virtuous cycle can be created, the Chinese robot industry will undoubtedly expand in the next five to ten years.

This article was first published by Caixin Global as "In Depth: The March of Chinese Robots Into Domestic Factories". Caixin Global is one of the most respected sources for macroeconomic, financial and business news and information about China.

![[Big read] When the Arctic opens, what happens to Singapore?](https://cassette.sphdigital.com.sg/image/thinkchina/da65edebca34645c711c55e83e9877109b3c53847ebb1305573974651df1d13a)

![[Video] George Yeo: America’s deep pain — and why China won’t colonise](https://cassette.sphdigital.com.sg/image/thinkchina/15083e45d96c12390bdea6af2daf19fd9fcd875aa44a0f92796f34e3dad561cc)