[Big read] Can ASEAN build its own battery future in a world powered by China?

As US–China competition reshapes global supply chains, batteries have become the next frontier of geopolitical power. With China dominating production, can ASEAN chart an independent course — or will it remain plugged into Beijing’s grid? Lianhe Zaobao journalist Thomas Li Tao speaks to academics and experts on the implications for ASEAN.

China–US trade relations have entered another turbulent phase. As US President Donald Trump threatens to impose a 100% tariff on Chinese goods, China has announced a new round of export restrictions effective 8 November. Unlike previous bans on rare earth exports, Beijing now appears to have found a new trade weapon — batteries.

China’s latest export ban covers large-scale energy-storage lithium batteries, cathode and anode materials, and battery-manufacturing machinery. These technologies span nearly the entire battery supply chain — a field where China dominates almost every segment. According to Bloomberg New Energy Finance (BloombergNEF), China has long controlled around 70% of global lithium battery production. In Bloomberg’s most recent Global Lithium-Ion Battery Supply Chain Ranking, China once again claimed the top position, with analysts citing low electricity costs and strong infrastructure development as key reasons for its lead.

With rising energy demand and growing emphasis on renewables, the question arises: Can ASEAN develop a complete battery industry chain?

ASEAN: Late entrant with limited capacity

Research by McKinsey indicates that outside China, Europe, and North America, the current undersupply of lithium-ion batteries could rise from 80 GWh in 2025 to 300 GWh by 2030. It also highlighted that in Southeast Asia, the rapid surge in EV adoption is a primary driver of this growing deficit.

Late start, limited output — but ASEAN’s regional division of labour is taking shape

The aforementioned McKinsey study found that outside China, Europe, and North America, the supply gap for lithium batteries will continue to widen, from 80 GWh in 2025 to 300 GWh in 2030. The report notes that in Southeast Asian countries, the rapid increase in EV numbers is the main driver of this growing shortfall.

Data show that in 2024, electric vehicle (EV) sales in six ASEAN countries reached approximately 350,000 units, accounting for 13% of the total passenger car market. If this growth momentum continues, annual EV sales in the region are projected to reach around 8.5 million units by 2035.

As the world accelerates its shift toward green energy, key technologies such as lithium batteries, electric vehicles, and energy-storage systems have gradually become the focus of national policies and new engines of industrial upgrading. With rising energy demand and growing emphasis on renewables, the question arises: Can ASEAN develop a complete battery industry chain?

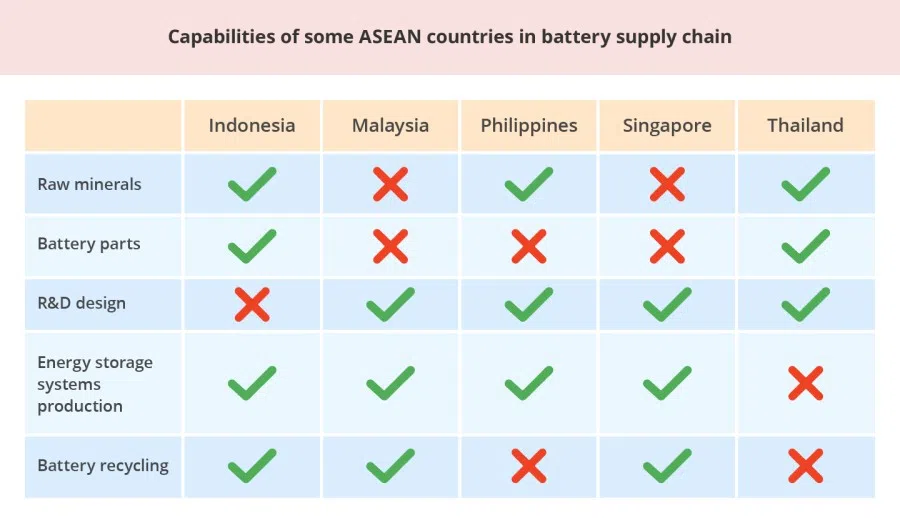

Compared with China, ASEAN’s battery production remains modest and relatively late to start. A report by the International Energy Authority (IEA) notes that Indonesia accounts for half of the world’s nickel mining output, yet its first EV-battery and graphite anode plants only began operations in 2024.

Nevertheless, ASEAN’s battery production is steadily increasing. In Bloomberg’s latest global lithium-battery supply-chain ranking, Indonesia climbed four places to 13th, making it the only ASEAN nation in the top 15.

On production lines across ASEAN countries, cheaper lead-acid batteries still dominate the market, with Thailand and Malaysia being the strongest exporters. However, as the global market shifts toward cleaner and more efficient lithium-based alternatives, exports of lead-acid batteries are on the decline.

“Lithium-ion battery systems will continue to be dominant in the next five to ten years,” said Michael Stanley Whittingham, one of the inventors of the lithium battery and 2019 Nobel Chemistry laureate, in an interview with Lianhe Zaobao.

Lithium batteries dominate as alternative materials emerge

A report titled Navigating the Battery-Related Landscape in Southeast Asia and Beyond, jointly released by the Singapore Battery Consortium and multiple ASEAN research institutions, notes that unlike its regional neighbours, Singapore does not possess large-scale manufacturing capacity within the battery value chain.

Nevertheless, Singapore plays a crucial role in several other key areas, including materials research and development, battery assembly and thermal management, testing, and recycling.

But among the many types of batteries, which technology holds the greatest potential for the future?

“Lithium-ion battery systems will continue to be dominant in the next five to ten years,” said Michael Stanley Whittingham, one of the inventors of the lithium battery and 2019 Nobel Chemistry laureate, in an interview with Lianhe Zaobao. Yet, he emphasised that lithium batteries still have room for improvement, and that lithium will remain at the core of ongoing innovation.

Whittingham explained that for safety reasons, the anode material in current batteries is mainly graphite, a form of carbon.

“Right now we need 72 grams of carbon to store seven grams of lithium, and the carbon takes up half the volume of the cell.”

However, if the safety risks of pure lithium metal anodes can be resolved, the performance of lithium batteries could improve dramatically.

“That’s how we started out 50 years ago. It wasn’t safe, but if we can go back to that, we can double the energy density of the batteries. So your car battery will be half the size. Your watches will last two days.”

While lithium batteries remain the mainstream technology for both energy storage and electric vehicles today, experts caution that they are not suitable for every scenario, and may struggle to meet the diverse energy-storage demands of the future.

At present, Chinese companies CATL and BYD have already launched commercial sodium-ion batteries and plan to mass-produce them on a large scale.

An infinite supply of sodium in nature that can power flights

“The development potential of lithium-ion batteries is limited when it comes to meeting all applications,” said Professor Chiang Yet-Ming, a materials science and engineering expert at the Massachusetts Institute of Technology (MIT), in an interview.

For large-scale grid storage applications that require high-capacity energy storage, lithium batteries are not the most cost-effective option.

“The longer the energy needs to be stored before discharge, the lower the cost per unit of energy must be,” he explained.

In such cases, low-cost iron–air and sulphur-based batteries are better alternatives. But another potential substitute for lithium might be found much closer to home — in the kitchen.

The main element in table salt, sodium, sits next to lithium on the periodic table and shares similar energy-storage properties. What makes sodium particularly appealing to industry is its abundance and low cost. Unlike lithium, which is concentrated in geopolitically sensitive regions and requires complex extraction processes, sodium is virtually inexhaustible, readily available in seawater and rock deposits.

At present, Chinese companies CATL and BYD have already launched commercial sodium-ion batteries and plan to mass-produce them on a large scale. Industry analysts predict that, once mass production is achieved, sodium batteries could cost 30% to 70% less than lithium batteries.

Professor Chiang revealed that his research team is developing a sodium–air fuel cell, which may one day power aircraft.

“To be used in aviation, batteries must achieve an energy density of at least 1,000 watt-hours per kilogram — about four to eight times higher than current EV batteries,” he said.

“Our prototype single-cell units are already approaching that target.”

With the growing use of sustainable energy, large-scale Battery Energy Storage Systems (BESS) are also becoming a major industry focus.

According to Bloomberg data, a decade ago, the utility-scale battery capacity in the US was nearly zero. By 2024, it has reached 26 gigawatts, and the US is expected to add up to 136 gigawatts of new battery capacity over the next decade.

Financing and technical standards remain key bottlenecks

Across the region, Singapore and its neighbours in ASEAN are working to build an integrated ASEAN power grid to enhance cross-border energy trade, particularly in clean energy sources such as solar power.

However, many clean energy sources are intermittent, meaning their output fluctuates sharply depending on weather conditions, posing a challenge to grid stability. In this context, energy storage systems (ESS) act like giant power banks for the grid — storing energy when supply is abundant and releasing it when demand peaks, thereby stabilising the network.

“We are no longer restricting our discussions to energy storage systems in Singapore, and are no longer restricted by local physical or geographical constraints. Instead, we are talking about regional support.” – Peter Ng, consultant to Narada Asia Pacific

Peter Ng, an industry veteran and consultant to Narada Asia Pacific, noted that the scale of ESS projects in ASEAN has expanded significantly. “Gone are the days when we said a few hundred kilowatt-hours is a big deal; now we are in the age of gigawatts.”

For example, in 2023, Sembcorp Industries launched a large-scale energy storage system on Jurong Island in Singapore, capable of storing enough energy in a single full charge to power about 24,000 four-room Housing Development Board (HDB) flats for one day — then the largest of its kind in Southeast Asia.

Huang added that as ASEAN’s grid integration deepens, energy storage systems will no longer be limited to meeting local demand. “We are no longer restricting our discussions to energy storage systems in Singapore, and are no longer restricted by local physical or geographical constraints. Instead, we are talking about regional support.”

Despite the progress, financing and cost pressures remain major bottlenecks for the energy storage industry. Small and medium-sized enterprises (SMEs) and startups often struggle to bear the high upfront investment and long payback cycles.

Philip Lee, vice president of Singapore-based Green Tenaga, vice president of Green Tenaga, a Singapore-based energy storage firm, said the company is exploring opportunities in Malaysia and the Philippines, including a potential project that integrates solar microgrids with energy storage systems to power towns or industrial parks.

Lee said that even though battery cost has been falling for many years, the initial capital outlay is still very high. “It is very difficult for newcomers to enter the market. A huge amount of capital is needed to survive for two to three years before good returns on the investment materialise.”

Narada’s Ng said that ASEAN countries lack unified technical standards for various stages of battery production, making cross-border collaboration and product certification difficult. In addition, the fragmented supply chain layout hampers the development of a highly efficient, integrated system.

Moreover, the deployment of large-scale ESS projects still faces regulatory uncertainty, resulting in complex approval procedures and slowing the industry’s overall growth momentum.

Battery fires prompt ASEAN to push for regional safety standards

On 26 September, a fire broke out at a data centre in Daejeon, South Korea. Shockingly, this administrative data hub had no backup system, resulting in the permanent loss of nearly 860TB of data and bringing government operations to a standstill.

Local media mockingly remarked how digital-era operations are less reliable than ancient dynasties’ paper archives. Subsequent investigations revealed that the fire was caused by a battery explosion, which triggered thermal runaway — a chain reaction leading to uncontrollable overheating.

“We’ve invited each country to share their challenges — from regulatory frameworks, infrastructure, and charging-station layout to issues encountered in actual use, whether in vehicles or data centres.” – Lim Chin Chin, Director, Home Team Science and Technology Agency (HTX) Forensics Centre of Expertise

Beyond data centres, EV fires pose another growing risk. In Singapore, EV-related fires account for about 0.7% of all automobile fires.

While that figure seems low, Lim Chin Chin, director of Home Team Science and Technology Agency (HTX) Forensics Centre of Expertise, told Lianhe Zaobao that the rising number of EVs makes this a pressing public safety concern.

In April, Singapore organisations like the HTX Forensics Centre of Expertise, A*STAR, and SBC moved to establish a battery safety cooperation framework with their ASEAN counterparts in the battery industry.

Since April 2025, the HTX Forensic Science Centre, A*STAR, and the Singapore Battery Consortium (SBC) have teamed up with battery industry agencies across ASEAN to establish a regional cooperation mechanism on battery safety.

“We’ve invited each country to share their challenges — from regulatory frameworks, infrastructure, and charging-station layout to issues encountered in actual use, whether in vehicles or data centres.”

Some existing international standards are also not applicable to tropical regions. For example, certain tests assess battery performance in extreme cold, which is clearly not appropriate for Southeast Asia’s year-round tropical climate.

Lee noted that there is still a lack of relevant standards, and through this cooperation platform, countries can identify blind spots and define standards that are truly applicable to the region.

Chiam Sing Yang, deputy executive director of A*STAR’s Institute of Materials Research & Engineering (IMRE) and SBC technical director, cautioned that introducing purely local standards without broad international recognition could limit export opportunities and industry collaboration.

“If we just say we’ll sell to our own standard, there’s a market access issue, because then whether your car makers will test them to the sellers, or your ESS makers will test them to these standards, depends on how big your market is, basically.”

...a structural oversupply has emerged in the global market, making it nearly impossible for other countries to compete with China on price. – Whittingham

ASEAN’s opportunity lies in niche industries

As tariff wars and geopolitical tensions begin to engulf the battery supply chain, how should ASEAN nations respond?

OCBC Environmental, Social, and Governance (ESG) analyst Ong Shu Yi noted that components of the EV supply chain, such as batteries, represent major clean energy exports from Malaysia and Thailand to the US. “Although US tariffs on EV-related products are lower than those on solar products, elevated US tariffs can still impact these countries’ roles in the global EV supply chain.”

She pointed out that the growing momentum of EV adoption around the world may also encourage EV-related manufacturers in ASEAN to seek a broader customer base beyond the US market.

Nobel Laureate Whittingham feels it is technically possible but financially challenging for other countries to set up their own battery supply chains, noting that the costs will be significantly higher than those of the batteries currently on the market.

He added that a structural oversupply has emerged in the global market, making it nearly impossible for other countries to compete with China on price. “Chinese batteries are being sold at below cost — that’s essentially dumping. And there are simply too many battery manufacturers in China, which keeps pushing prices down.”

ASEAN can cultivate the small-device battery market

When asked whether ASEAN and other regions could decouple from China in the battery supply chain, Whittingham said the answer largely depends on the types of chemical materials used. If alternative supply chains outside of China can be developed for some of the raw materials and technologies, that could help regional countries achieve a degree of diversification in their industrial layout.

Whittingham cited the example of ExxonMobil. “ExxonMobil used to make some of the best separators for lithium ion batteries in the world, and they’re made in their Japanese affiliate. Then, they got out of Japan, so they don’t do that anymore, but they are now drilling for lithium in Arkansas, so they’re going to be a large lithium manufacturer.”

...there is still room for development in smaller battery segments, such as grid-scale energy storage systems and wearable devices. – Whittingham

As for what role ASEAN countries should play in the battery industry — and how governments might support it — Whittingham advised avoiding the highly competitive, low-margin electric vehicle sector, and instead developing niche industries.

He noted that the EV battery market is not dominated by Chinese companies alone, as Korea’s Samsung, LG, and SK, as well as Japan’s Panasonic, are also formidable players. “It’s a cutthroat business, so you’ll never make any money.”

In contrast, there is still room for development in smaller battery segments, such as grid-scale energy storage systems and wearable devices.

A brief history of batteries

The history of batteries dates back to 1800, when Italian scientist Alessandro Volta invented the Voltaic Pile, the world’s first device capable of producing a continuous electric current. Since then, battery technology has undergone multiple stages of evolution.

1860s: French engineer Gaston Planté invented the lead-acid battery, which remains widely used today for automotive ignition systems.

1899: Swedish scientist Waldemar Jungner developed the nickel-cadmium (NiCd) battery, suitable for portable electronic devices.

1976: Michael Stanley Whittingham proposed the first lithium battery prototype. Later, John B. Goodenough, a German-American physicist, discovered key cathode and anode materials that made lithium batteries viable.

In 1985, Japanese engineer Akira Yoshino launched the first commercial lithium-ion battery.

The trio of Whittingham, Goodenough, and Yoshino were jointly awarded the 2019 Nobel Prize in Chemistry for their pioneering work.

2000s: Lithium-ion batteries gradually replaced nickel–metal hydride (NiMH) and lead-acid batteries, becoming the main power source for smartphones, electric vehicles, and energy storage systems.

This article was first published in Lianhe Zaobao as “全球电池业博弈升温 亚细安如何夹缝中突围?”.